Site n'ịhọrọ monomers kpọmkwem, mmadụ nwere ike nweta polyamide na-egbuke egbuke na nke na-adịgide adịgide.Ndị kristal dị ntakịrị nke na ha anaghị achụsasị ìhè a na-ahụ anya, ihe ahụ na-apụtakwa ìhè n'anya mmadụ-ihe a maara dị ka microcry stallinity.N'ihi kristal ya, ihe owuwu microcrystalline na-ejigide ihe ndị dị mkpa dị ka nguzogide mgbawa nrụgide - na-enweghị igwe ojii.Ogo nke crystallinity bụ ihe a na-eleghara anya, Otú ọ dị, na ọ nweghị mmetụta ọjọọ na omume shrinkage nke akụkụ ndị a kpụrụ akpụ.Ọ na-enweta ihe mgbochi isotropic yiri ya dị ka ihe amorphous.

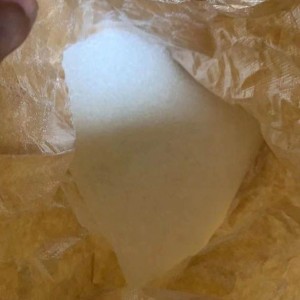

Ọ bụ obere viscous, polyamide na-adịgide adịgide maka ịkpụzi injection.